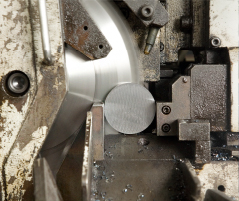

The abrasion-resistant tip ensures a stable service life

and a neat cutting surface in the cutting

of carbon steel and alloy steel materials.

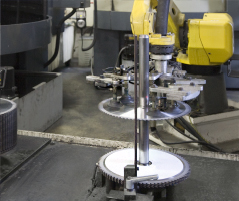

With a balanced array of state-of-the-art processing machines, we are working to enhance our productivity and reduce delivery time on a daily basis. Through our test systems, we utilize equipment such as destruction testing equipment, a hardness tester, and a 3D microscope to conduct tests from multiple aspects and eliminate defective products. In addition, we own three cutting machines to conduct our products’ cutting quality verification and durability tests in-house, which is one of our advantages. In our production line, each worker is strongly committed to not leaving any defects for subsequent processes. This commitment enables us to maintain and improve our quality.

最新鋭の加工機をバランスよく配置し、生産能力の増強と納期の短縮に日々努めています。検査体制は、破壊試験機・硬度計・3Dマイクロスコープなどを駆使し、多方面からの検査を行う事で不良品の根絶を目指しています。また、3台の切断機を有し、切断品質の確認と耐久テストも社内で実施できるのが強みです。製造現場では、各作業者が不良品を次の工程に回さない強い信念を持って取り組んでいます。その取り組みで品質の維持・向上につなげています。